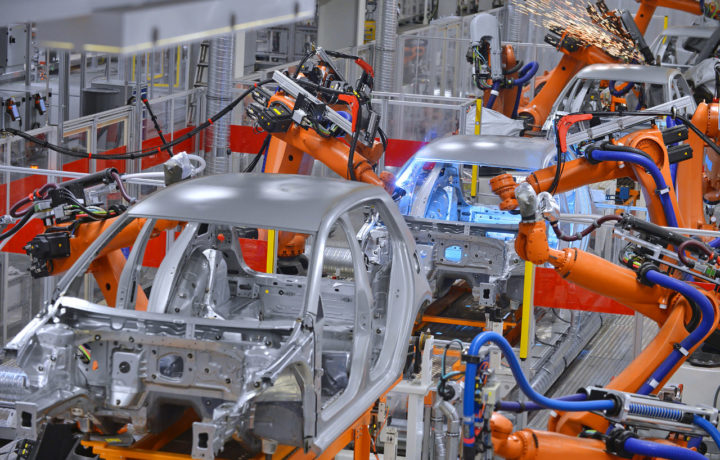

Manufacturing operations of a business must be able to keep up with the changing times for the business to be a successful one. What trends are shaping the world of manufacturing in 2021? Read on to find out the latest.

1. Greater reliance on IoT

The Internet of Things isn’t new. It has been used across several industries to speed up processes and increase efficiency. This is also true for manufacturing.

A greater reliance on the Internet of Things in 2021 has made it possible for manufacturers to plan more strategically by making use of real time data. With smart technology and connected devices allowing for easy access to big data, a greater level of automation and control can be facilitated. This helps to connect logistics, power grids, assets, and allows for smart manufacturing processes to be implemented.

2. Green manufacturing gains prominence

Manufacturing consumes a lot of energy, so it’s only natural that there has been concern over the sustainability of the entire process.

Green manufacturing is picking up in popularity due to concerns over environmental sustainability. This has led to greater demand for renewable resources of energy to power factories. It has also resulted in recovering as well as repurposing of product materials to lessen the carbon footprint. The aim is to reduce the waste generated so that processes can be designed to have the least negative impact on the environment.

3. Lean manufacturing is the buzz word

Lean manufacturing or lean thinking has proven to be a game changer in the world of manufacturing. It has helped to plan processes strategically so that wastage is minimized and productivity is maximized.

4. Predictive maintenance is still key

The greater level of digitization in the manufacturing space has made it possible to monitor machine performance and carry out predictive maintenance. Smooth machine and equipment functioning is necessary to ensure that products are ready in the time frame when the customer needs. Machine breakdown can result in costly repairs and downtime, affecting the overall profitability of business operations.

The increased use of predictive analytics has made it possible to carry out predictive maintenance. Monitoring can be done while equipment is being operated, meaning that there is no interruption in the manufacturing process.

Predictive maintenance makes it possible to carry out repairs much before they are actually required. This extends the lifespan of the equipment and ensures that there are no delays in operations.

5. 3D printing for faster and cheaper production

It may seem like something out of a science fiction movie, but the use of 3D printing to improve manufacturing processes is a trend that is picking up. 3D printing allows for prototyping of products in a cost-effective manner. The amount of time spent on tooling is avoided and new products can be tested and launched in response to the demand for them.

You won’t have to spend on heavy equipment or worry about molds, fixtures, and jigs. Any problems can also be identified and worked on with the use of 3D printing technology.

6. Greater resilience of the supply chain network

A broken or overburdened supply chain will put a stop to manufacturing operations. Businesses have realized this the hard way which is why there is a trend towards making the supply chain network more resilient. Multi-sourcing is being relied on more with an expansion of the supplier list. Near shoring supply chains is another way in which supply chain issues are being resolved.

The use of AI and greater digitization has also made it possible to monitor supply chains and track issues more effectively.

7. Focus on B2C

2021 has seen a shift from business focus on B2B to B2C sectors. With efficient manufacturing processes, it is possible to produce based on customer demand by relying on the pull method of production. This will help businesses sell at the MSRP instead of wholesale prices. It will also allow for a greater level of control over the price of the product as well as brand image.

With big data analytics, customer data can be made use of wisely to draw inferences and build lasting relationships. It also makes it possible for products to enter the market a lot faster rather than having to rely on retail sales.

Now Over to you…

Is your business keeping up with the trending times? It’s imperative to do so if you want to have an edge over your competition.

Cover photo credit: Oğuzhan Karaca / Pexels