The manufacturing industry, often associated with heavy machinery and traditional processes, is undergoing a profound transformation thanks to blockchain technology. While blockchain is commonly associated with cryptocurrencies like Bitcoin, its applications extend far beyond the financial sector.

In this article, we’ll explore how blockchain technology is disrupting manufacturing, revolutionizing supply chains, enhancing transparency, and paving the way for a new era of efficiency and trust in the industry.

![]()

The Power of Blockchain in Manufacturing

Blockchain, at its core, is a decentralized and tamper-proof ledger that records transactions across a network of computers. Each record, or block, is linked to the previous one, forming a chain of blocks. This technology’s key strength lies in its ability to create a secure, transparent, and immutable record of transactions and data.

In manufacturing, this translates into several game-changing advantages:

1. Supply Chain Transparency

One of the most significant impacts of blockchain technology in manufacturing is the enhancement of supply chain transparency. In a complex global supply chain, tracking the movement of raw materials, components, and finished products can be a daunting task. Blockchain introduces transparency at every step.

Each time a product changes hands, the transaction is recorded on the blockchain. This means that every party involved, from suppliers to manufacturers to distributors, has access to an unalterable record of the product’s journey. Any discrepancies or delays can be quickly identified, reducing the risk of fraud, counterfeiting, and errors.

Furthermore, blockchain’s transparency extends to consumers, who can access information about the products they purchase, including their origins, certifications, and environmental impact. This transparency builds trust and empowers consumers to make informed choices.

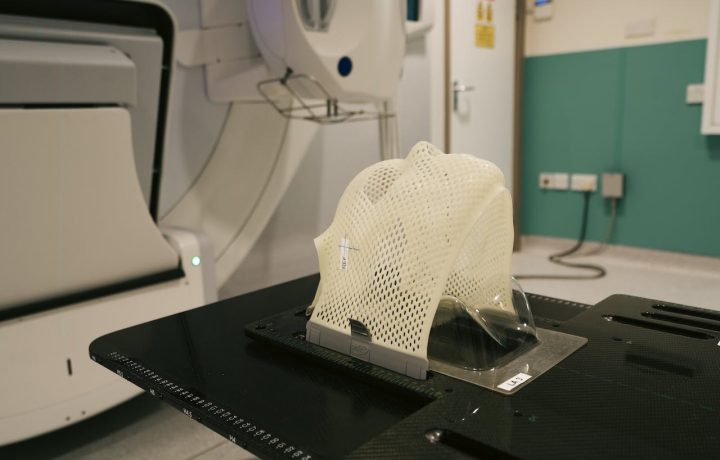

2. Quality Assurance and Certification

In manufacturing, product quality is paramount. Blockchain technology allows for the creation of a digital twin—a virtual representation of a physical product—that can be continuously updated throughout its lifecycle. This digital twin can store data related to manufacturing processes, materials used, inspections conducted, and maintenance history.

Manufacturers can use blockchain to prove the authenticity and quality of their products, helping them gain customer trust and comply with industry regulations. Consumers, in turn, can verify the origins and specifications of the products they purchase, promoting transparency and product safety.

Furthermore, blockchain’s transparent and tamper-proof nature ensures that certification bodies can securely issue and verify quality and safety certifications. This reduces the potential for counterfeit certifications and strengthens the credibility of the certification process.

3. Streamlining Supply Chain Management

Supply chain management often involves numerous intermediaries, documentation, and coordination efforts. Blockchain simplifies this complexity by enabling smart contracts—self-executing contracts with predefined rules and conditions. These contracts can automate tasks like inventory management, order processing, and payments.

For example, when a manufacturing company places an order with a supplier, a smart contract can automatically trigger the release of funds as soon as the goods are received and verified. This eliminates the need for manual paperwork, reduces administrative overhead, and accelerates the flow of goods.

Furthermore, blockchain’s ability to provide real-time visibility into supply chain processes empowers businesses to make data-driven decisions. They can optimize routes, inventory levels, and production schedules based on accurate and up-to-date information.

4. Reducing Counterfeiting and Fraud

Counterfeit products pose a significant threat to manufacturers and consumers alike. Blockchain’s immutable ledger makes it nearly impossible to counterfeit products or manipulate data. Every product’s unique identifier can be recorded on the blockchain, and consumers can verify the authenticity of a product by scanning a QR code or accessing a blockchain-based database.

This level of security not only protects manufacturers’ brands and revenues but also ensures that consumers receive genuine, safe products.

Moreover, blockchain’s ability to trace the origin of products and materials makes it a valuable tool in identifying and preventing fraud within the supply chain. By ensuring that products are sourced from trusted suppliers and that their journey is recorded on the blockchain, manufacturers can minimize the risk of fraudulent activities.

5. Promoting Environmental Sustainability

Blockchain can also play a role in promoting environmental sustainability in manufacturing. By tracking the lifecycle of products and materials, manufacturers can reduce waste and make informed decisions about recycling and reusing materials. Blockchain can enable the creation of a circular economy, where products and materials are continually repurposed, reducing the environmental impact of manufacturing.

Additionally, blockchain can be used to record and verify sustainable practices, such as the use of eco-friendly materials and energy-efficient manufacturing processes. This information can be shared with consumers, allowing them to make environmentally conscious choices when selecting products.

![]()

Challenges and Adoption

While blockchain holds immense promise for manufacturing, there are challenges to overcome. These include the need for standardization, integration with existing systems, and ensuring data privacy. Additionally, blockchain technology is still relatively new in the manufacturing sector, and widespread adoption will require education and investment.

Manufacturers need to invest in the necessary infrastructure, including blockchain nodes and data storage solutions, to fully leverage the technology’s benefits. Additionally, collaboration among industry stakeholders is essential to establish common standards and protocols for blockchain implementation.

Conclusion

Blockchain technology is ushering in a new era of transparency, efficiency, and trust in manufacturing. By providing a secure and immutable record of transactions and data, blockchain is disrupting traditional manufacturing processes and supply chains. Manufacturers that embrace blockchain can enhance their operations, build trust with customers, and position themselves as leaders in an increasingly digital and transparent industry.

The era of blockchain-powered manufacturing has arrived, and the possibilities are limitless.