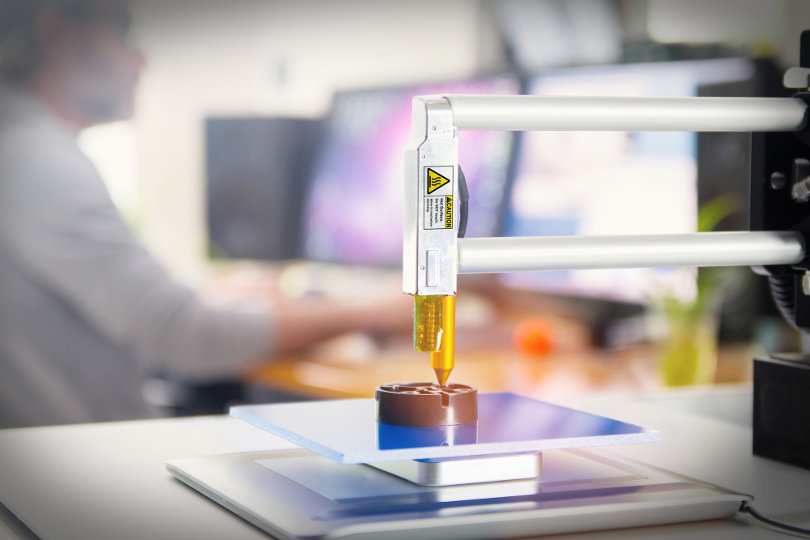

Green manufacturing is a topic that very few people are familiar with, yet it is critical to understand for firms trying to make meaningful progress. So, what exactly do we mean by green manufacturing?

In the manufacturing industry, green manufacturing principles provide renewable production systems and ecologically responsible practices. The procedures used to assist manufacturers to reduce their influence on the environment, implement positive change, and inspire other enterprises to fall into line.

Sustainability refers to the production of goods using cost-effective methods that reduce adverse environmental impacts while minimizing wastage of raw materials and energy.

Sustainability is a big real in manufacturing today. The manufacturing sector has changed as a result of this focus on sustainability.

Goals of Green Manufacturing

Green manufacturing’s principal objective is to save energy and reduce pollution. This is done by decreasing or eliminating harmful compounds that are created as residues during the production process.

Green manufacturing is defined as the production of environmentally friendly items for consumers or the production of conventional products in a manner that is less detrimental to the planet. Green manufacturers strive to reduce pollution, conserve raw materials and energy, and create goods that are safer for customers. Many of these businesses closely follow ISO and LEED green quality requirements, and also green supply chain management practices.

Why Green Manufacturing is Relevant

Ever since the late 1800s, the earth’s average temperature has increased by around 2.12 degrees Fahrenheit. Rising carbon dioxide emissions, as well as other air pollutants, have contributed significantly to the change. The last 40 years have seen the most warming, with the last seven years becoming the hottest.

Researchers have been able to analyze information about our environment and its climate all across the world thanks to satellites and other technological breakthroughs. The indicators of climate change are clear in this data, which has been recorded over several years.

The research community now has the support of the people of North Americans. The impending threats of man-made climate change are real, and today’s gains must not come at the expense of the planet we are going to pass on to the succeeding generations. More businesses are emphasizing preservation and green manufacturing processes as the cornerstones of good corporate citizenship.

In this context, green manufacturing is now more relevant than ever. More and more enterprises are realizing it and adjusting their production facilities accordingly. It is not just an issue of the future- it is now a very contemporary problem that we need to deal with collectively.

How Can a Manufacturing Unit Practice Green Manufacturing?

There are many ways a manufacturing unit can go green:

1. Production from Renewable Energy

Manufacturing consumes a significant quantity of energy. Corporations can alternatively obtain energy from renewable sources. It would put less demand on energy production while also lowering the environmental impact. Renewable energies have become much more economical and accessible as technology advances. Given the importance of the choice, it should be adopted by a growing number of production units.

2. Improve the energy efficiency

Companies can not only alter their power source, but they can also reduce the quantity of energy required to manufacture products. The use of more efficient tools and machinery reduces the need for heavy energy resources. It has a favorable impact on the environment as well as productivity.

3. Controlling pollution

A company’s production practices can have a significant influence on the environment. This is accomplished by the use of recycling and the development of modern technology to reduce pollution. Pollution occurs when dangerous chemicals get released into the air, water, or land. Improved waste management will have a direct impact on pollution reduction.

4. Natural Resource Conservation

Large manufacturing operations typically come at the cost of the environment. Manufacturers can contribute to environmental protection by pledging to conserve nature reserves.

Takeaway

As we can see, green manufacturing is no longer an option. It is increasingly becoming an inevitability. Businesses too can reap profits from practicing green manufacturing. Some of the benefits include getting the support of an environmentally conscious customer base, having access to government incentives, and inventing more efficient production techniques. Apart from these obvious advantages, the positive impact on health and well-being cannot be reduced to their monetary equivalent.

Many top global companies have already adopted green manufacturing techniques and are seeing considerable success.